Silicon Carbide Wafer Laser Cutting Systerm

Uses ultra-short pulse laser to achieve high quality and high efficient cutting of silicon carbide wafer.

Inquiry Phone:+86-400 8017 001

Inquiry Phone:+86-400 8017 001 E-mail:contact@delphilaser.com

E-mail:contact@delphilaser.com■ Specifications:

◆ Processing object: silicon carbide wafers

◆ Laser type: Infrared picosecond pulsed laser

◆ Cooling method: air-cooled

◆ X-axis: stroke 450mm, resolution 0.1μm

◆ Y-axis: stroke 700mm, resolution 0.1μm

◆ Z-axis:stroke 20mm,resolution 0.1μm

◆ θ axis: travel 120°, resolution 0.001°

◆ Maximum cutting thickness: 500μm

◆ Maximum speed of cutting axis: 500mm/s

◆ Processing size: 6 inches(upgradeable to 8 inches)

■ Applications

Aerospace and Power Electronics Industries.

Specifically designed for cutting wafers with silicon carbide (SiC) substrates used in microwave devices and power devices.

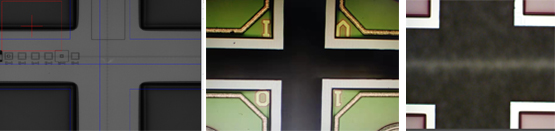

■ Samples

For more information