2025-01

Recently, the China National Intellectual Property Administration (CNIPA) announced the eva1uation results of the 25th China Patent Awards. Suzhou Delphi Laser Co., Ltd. was honored with the "China Patent Excellence Award" for its patent titled "Device and Method for Asymmetric Beam Splitting Laser Processing of Transparent Materials", further demonstrating the company's strength in technological innovation. Since its establishment in 2005, Delphi Laser has consistently aligned with national R&D demands, placing high importance on intellectual property (IP) and actively advancing its IP-driven corporate strategy. The company has set up a dedicated IP management department, formulated strategic IP plans, and enhanced overall IP awareness. These efforts have earned it the titles of "National Intellectual Property Advantage Enterprise (2019)" and "National Intellectual Property Demonstration Enterprise (2022)". Moving forward, Delphi Laser will continue to uphold the principle of innovation-driven development, leverage its exemplary role, increase R&D investment, and actively explore new technologies and applications to enhance its core competitiveness. The company remains committed to achieving its goal of becoming a globally competitive IP powerhouse. About the China Patent Awards: Co-organized by the CNIPA and the World Intellectual Property Organization (WIPO), the China Patent Awards represent the only government-backed accolade in China that recognizes outstanding patented inventions. The awards aim to strengthen IP creation, protection, and utilization, promote high-quality economic development, and honor patentees and inventors (designers) who have made significant contributions to technological innovation and socio-economic progress.

2024-11

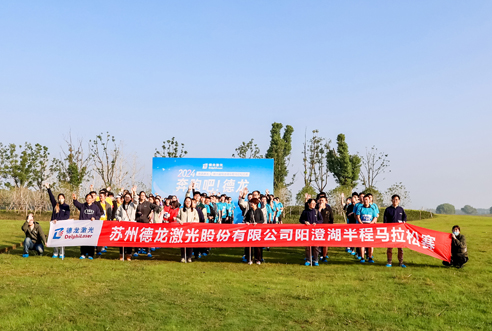

In November, the autumn breeze in Suzhou is just right, and Delphi Laser's annual marathon event is once again underway. The people of Dephi Laser, with their spirited attitude, measure the earth with their footsteps and write perseverance with their sweat. Wonderful Moments On the racecourse, the athletes from Delphi Laser showed exceptional style, surpassing themselves, moving forward courageously, and never giving up! It is worth mentioning that the female participants in this year's marathon competition were no less than their male counterparts, becoming a beautiful sight on the track. Award Group Photos 20km Group 10km Group 5km Women’s Group 5km Men’s Group Team Award: Operations Center Running never stops, and innovation continues without end. All employees of Delphi Laser will approach their work and life with greater enthusiasm, a strong body, and a spirited attitude. Looking ahead, Delphi Laser will run hand-in-hand with partners both inside and outside the industry to create brilliance together! Looking forward to next year’s Delphi Laser Marathon, continuing to create even more wonderful moments!

2024-09

Material Innovation, Empowering Development Delphi Laser As the foldable smartphone market continues to surge, innovative materials have become the key to advancing this technology. This has heightened the demand for high-precision laser processing equipment. Delphi Laser, with its deep expertise and commitment to innovation, has strategically positioned itself in the foldable screen market. Its equipment has been successfully deployed in production lines, earning high recognition from clients and providing precise, efficient solutions for intelligent manufacturing in every detail of foldable smartphones. 1、Cover Glass Processing Delphi Laser 1)UTG Glass Cutting System Ultra-Thin Glass (UTG) is increasingly favored for foldable display covers due to its ultra-thin, flexible, highly transparent, and high-temperature-resistant properties. Addressing the growing demand for UTG, Delphi Laser offers specialized UTG glass cutting equipment that ensures high-efficiency, precise cutting, enhancing production efficiency and yield rates. Advantages: Non-contact processing minimizes material damage and operating costs. High-speed, precision cutting with CCD vision alignment. Direct CAD import for quick and efficient cutting of various shapes. Industrial-grade design ensures stable 24/7 operation. Optional automated loading/unloading for increased efficiency and reduced labor. Samples: 2)CPI Laser Precision Micro-Processing System Transparent Polyimide (CPI), a critical material for foldable screens, offers stable performance, technical maturity, and cost advantages. Delphi Laser's CPI micro-processing equipment delivers high-precision, efficient cutting tailored to this key material. Advantages: High-speed processing with excellent precision, boosting productivity. Minimized thermal effects, reducing edge chipping. Advanced processing systems enable precise parameter and pattern matching. 3)Film Cutting and Stripping Integrated System This automated solution protects display covers from scratches and stains by efficiently handling film application and stripping. Delphi Laser’s cutting-edge design integrates laser cutting, vision alignment, and automated systems for seamless operation. Advantages: Automated tray transfer and robotic loading enhance productivity. Precision alignment ensures accurate cutting and film application. Customizable settings for various dimensions and positions. Stable, long-term operation supported by high-quality materials and software. 2、Carbon Fiber Processing Delphi Laser Carbon Fiber Cutting System Carbon fiber, known for its lightweight and high-strength properties, is essential in foldable smartphone structural designs. Delphi Laser’s advanced carbon fiber cutting equipment ensures smooth, burr-free edges and optimized production efficiency. Advantages: High-speed, precise cutting reduces thermal effects and edge damage. Integrated systems for automated loading, cleaning, waste removal, and inspection. High-power laser systems developed in-house for cost-effective, high-performance processing. Samples: 3、Metal Hinge Processing Delphi Laser Hinge Laser Welding System Metal hinges are critical components in foldable smartphones, providing structural support and enabling various folding mechanisms. Delphi Laser’s laser welding equipment ensures precise, high-quality welding for hinges, accommodating a variety of materials and designs. Advantages: Fast Welding Speed: Laser welding achieves high speed, significantly enhancing production efficiency and meeting the rapid manufacturing demands of foldable smartphones and other electronic products. Non-Contact Welding: As a non-contact process, laser welding minimizes stress impact on metal components. Controllable Welding Depth: By adjusting laser power and beam focus, precise control of welding depth is achieved, preventing defects from excessive or insufficient penetration. High Adaptability: Laser welding technology accommodates various sizes, shapes, and materials of metal hinges, offering greater design flexibility for foldable smartphones. Samples: 4、Flexible OLED Processing Delphi Laser 1)Fully Automated Flexible OLED Shaped Cutting System This system is capable of easily handling complex shapes and curved cutting requirements. It precisely addresses the intricate folding shapes of smartphones. The equipment is primarily used for the fine-tuning and processing of AMOLED module segments, where the OLED panels are integrally cut by laser to improve edge precision and achieve irregular shape cutting. The system is equipped with an automatic image positioning system, multiple feeding and unloading interfaces, AOI (Automatic Optical Inspection), and USC (Ultrasonic Cleaning), ensuring efficient high-speed cutting and stable, high-quality operation. Advantages: It uses a UV picosecond/femtosecond laser combined with a galvanometer scanning system, enabling fast irregular shape cutting. Cutting quality: HAZ (Heat-Affected Zone) ≤ 50μm Cutting precision: CPK ≥ 1.33 (@±30μm) Fully automated Inline/Offline design, further reducing labor costs Compatible with OCA integrated cutting Samples: 2)Fully Automated Flexible OLED Laser Drilling System The core of a foldable smartphone lies in its foldable screen, which must maintain excellent performance and appearance during both folding and unfolding. Delong Laser's fully automated flexible OLED laser punching equipment is specifically designed for the AMOLED module display area. It uses advanced laser technology for punching the OLED panels in the AMOLED module to expose components such as the camera and other devices. By precisely controlling the laser energy and beam quality, it provides a reliable solution for manufacturing flexible display devices. Advantages: Utilizes UV femtosecond laser with a scanning galvanometer system to meet the demand for fast laser punching. Cutting quality: HAZ ≤ 40μm, no cracks, no rainbow patterns. Cutting precision: CPK ≥ 1.33 (@ ±30μm). Samples: 3)OLED/LCD Laser Repair System In the development of foldable smartphones, the perfect presentation of each pixel is an unwavering pursuit of quality. Delong Laser's OLED/LCD laser repair equipment is equipped with high-precision laser technology and advanced AOI (Automated Optical Inspection) technology, providing excellent imaging quality. The chosen control system components are highly precise, enabling the automatic detection and accurate positioning of OLED/LCD screen hotspots. Whether dealing with bright spots, weak bright spots, or partial dark spots, laser repair can be performed. The equipment features a compact structure and operates stably and reliably. Key Advantages: The equipment features a compact structure with a well-organized layout. It offers excellent compatibility. The motion system is stable and responsive. It delivers high precision, user-friendly interfaces, and easy maintenance. A strong technical team provides robust support for equipment installation, commissioning, and after-sales maintenance. Samples: 5、PCB/FPC Processing Delphi Laser Picosecond Laser Precision Micro-Processing System PCB and FPC play crucial roles in foldable smartphones, together forming the complex and precise circuit system that ensures the normal operation and exceptional performance of the device. Delphi Laser's picosecond laser fine processing equipment, with its high precision, efficiency, and stability, is widely used in the fine processing fields of cutting, lid opening, and other applications for PCB, FPC rigid-flex boards, and related materials in foldable smartphones. The equipment utilizes advanced picosecond laser technology, meeting the stringent processing precision requirements for high-end electronic products such as foldable smartphones. Key Advantages: The equipment uses an independently developed high-power ultraviolet picosecond laser, offering high cost-effectiveness. It effectively controls the processing results, improving product edge collapse and thermal effects. The self-developed dual-station processing system is stable and reliable, significantly improving processing efficiency. The mature process system accurately calculates and splits graphics, ensuring the precise matching of processing parameters and design patterns. Innovation never stops, empowering the future Delphi Laser Future Outlook Delphi Laser remains committed to innovation and excellence in laser micro-processing. By continuously advancing its technology, Delphi Laser empowers intelligent manufacturing, shaping the future of foldable smartphones and beyond.

2023-10

On May 6, the "Chasing Light and Marching Forward"-Delphi Laser's first-anniversary celebration as a listed company and "Future of Photonics- Cutting-edge Photonics Technology and Industrial Innovation and Development Forum" were held by Delphi Laser in Suzhou. While reviewing and summarizing the past year as a listed company, Delphi Laser invited industry experts to focus on cutting-edge photonics technologies and their latest applications, discuss photonics technology innovation, look forward to the development of the photonics industry, empower the high-quality transformation and development of the photonics industry, and jointly promote the integration of government, industry, academia, and research institutes! Zhu Xiaoyan, Director of the Financial Development and Risk Prevention Bureau of the Suzhou Industrial Park, delivered a speech Wang Wenjie, Executive Director of Sunny Optical, delivered a speech Zhao Yuxing, Founder and Chairman of Delphi Laser, delivered a speech Forum site Delphi Laser continues to launch industry-specific equipment and new scenario application equipment with technical advantages. At this event, it also unveiled four products, attracting industry attention.

2022-07

Only when you are in Suzhou can you be successful The most wonderful creation in the park The 14th Suzhou International Elite Entrepreneurship Week and the 2nd Jinji Lake Scientist Forum on the morning of July 11 Grand Opening! The best relationship between city and talents is to resonate with the same frequency, make efforts in the same direction and achieve mutual success. 28 years, in the development process of the park from following to leading, from pilot to demonstration, a large number of leading talents and talented enterprises have emerged, and they struggle and advance together with the park. Many of these enterprises have leaped to the top of the market, and together they have written the most exciting music of talents in the process of building industrial clusters.At the opening ceremony, commemorative trophies were awarded to 14 newly listed talent companies, including Delphilaser. Zhao Yuxing, Chairman of Delphilaser, received the award on stage (sixth from right) Since its establishment in 2005, Delphilaser has been focusing on the field of laser fine micro-processing. After years of research and development, the company has obtained 36 invention patents, more than 110 utility model patents and 60 software copyrights, and has been honored as a key high-tech enterprise under the National Torch Plan and a national "small giant" enterprise. The company's products and technology have been unanimously recognized by the leading downstream enterprises, establishing the company's market position in China's laser fine microprocessing industry. Zhao Yuxing, Chairman of Delphilaser, received the award on stage (third from the right) Suzhou Industrial Park, as one of the regions with the highest degree of openness, the best development quality and efficiency, the strongest innovation vitality and the best business environment in China, provides strong guarantee and high-quality services for the development of Delphilaser. Delphilaser will also take the listing as a new starting point, continue to deepen technological innovation, management innovation and business model innovation, become the industry leader, climb a new professional peak, and make new contributions to the high-quality development of the park. Source of some pictures and text: Suzhou Industrial Park Release, Jinji Lake Pioneer This article belongs to Suzhou Delphi Laser Co., Ltd. (www.delphilaser.com), if reproduced, please indicate the company name and website For more information about our products and applications, please visit our website at Delphilaser official website:www.delphilaser.com Ali store:tbdelphilaser.com Or scan the following two-dimensional code to follow our WeChat service number

2022-06

Delphilaser's official website and promotional video are now online! In order to show the new corporate brand image, Delphilaser's official website (www.delphilaser.com) has been revamped and upgraded, and has been officially launched recently. At the same time, Delphilaser also launched a new corporate video, presenting a new corporate image in a comprehensive, three-dimensional and multi-angle manner. The official website of Delphilaser Upgrade has six sections: "About Delphilaser", "Product Center", "News Center", "Investor Relations", "Join Us" and "Contact Us", which makes it more convenient to browse products and obtain information. While displaying the company's product technology and spreading corporate culture, it is also a comprehensive service website with functions such as investment, recruitment, sales and after-sales. At the same time, the official website has also placedcompany's new promotional video.Prominent display of our corporate image,Communicate corporate values while further optimizing the visual experience of the corporate website. The upgraded website has reorganized the company's product categories and applications, with several sub-categories under each column and a clear and concise interface. You can search for the corresponding application solutions according to specific information such as "processing method", "industry application" and "processing material". The functional modules of the product detail page are reorganized to disseminate specific product information in various forms of text, pictures and charts, and to display the content of the corresponding sub-columns of the products in their entirety below. You can continue to view other related products, which improves the aesthetics and practicality of the website. Delphilaser has always been adhering to the concept of attaching importance to talents and taking the struggle as the basis, and welcomes all kinds of talents who have integrity, are dedicated enough, know the team and are brave enough to innovate to join. If you want to join us, you can check the positions suitable for you in "Join Us" and contact us. You can also tell us your needs online, and we will contact you at the first time. 17 years of hard work, 17 years of chasing the light forward. Since its establishment in 2005, Delphilaser has been focusing on the field of laser fine microprocessing. With this new upgrade, Delphilaser will continue to deepen product development, technological innovation and management innovation, and continue to firmly adhere to the corporate spirit of "integrity, dedication, teamwork and innovation" to empower modern manufacturing with advanced lasers! This article belongs to Suzhou Delphi Laser Co., Ltd.(www.delphilaser.com), if reproduced, please indicate the company name and website For more information about our products and applications, please visit our website at: Delphilaser official website:www.delphilaser.com Ali store:tbdelphilaser.com Or scan the following two-dimensional code to follow our WeChat service number

2022-06

On June 8, Wang Lupei, Deputy Secretary of Party Committee of Soochow University, and Jin Ge, Director of Admissions and Employment Department, visited Delphilaser and conducted a research and inspection on the theme of promoting employment by expanding jobs. Suzhou University leaders visited Delphilaser Secretary Wang and his party visited the exhibition hall of Delphilaser, visited the manufacturing workshop and had a comprehensive understanding of the business layout and development of the company, and the two sides also had an in-depth exchange on the patent technology, research and development of scientific and technological projects, and transformation of scientific and technological achievements. Company Showroom Tour Company manufacturing workshop tour At the exchange symposium, Secretary Wang introduced the main purpose of the event and the situation of the students in school, and expressed sincere gratitude on behalf of the university for the long-term support of Delphilaser to the work of the university and the careful cultivation of the alumni of the university. He said that Chairman Zhao Yuxing, as an alumnus of SU, had made outstanding achievements in the field of optoelectronics, and there would be more opportunities to share his experiences with students in the future, so that they could feel the power of outstanding alumni. Secretary Wang also expressed that on the basis of the continuous good cooperation between the two sides, he hoped that the cooperation in the fields of talent training, scientific research innovation and integration of industry and education could be further promoted. Wang Lupei, Deputy Secretary of Party Committee of Soochow University Zhao Yuxing, Chairman of Delphilaser Chairman Zhao Yuxing introduced the development scale, talent demand and business layout of Delphilaser. As an alumnus of SU, Chairman Zhao Yuxing has always been concerned about and supported the development of his alma mater. He said he would continue to strengthen the in-depth cooperation and exchange between the two sides, continue to carry out long-term cooperation mechanisms in talent training and technology research and development, and cooperate to build a platform for the integration of industry and education and school-enterprise cooperation. Xu Ruiyan, SU alumnus and product manager of the Semiconductor Division, shares her experience In Delphilaser, there are many alumni who also graduated from Soochow University, and they are working hard, being active and creating value for the company. Xu Ruiyan, who graduated from Soochow University in 2008, shared his work experience in Delphilaser at the meeting, saying that his alma mater is not only teaching knowledge, but also teaching people to behave. Since he joined Delphilaser in 2011, he has kept his original intention to learn and grow up in Delphilaser's big family, taking the excellent alumnus Mr. Zhao as a role model and playing his personal value better on the leading platform in the industry like Delphilaser. In the future, he will continue to work hard, learn more advanced technology in the industry and add to the laser business of Delphilaser. Group photo of school and enterprise In this exchange, the two sides discussed on joint training of scientific research talents, widening employment channels, joint scientific research and research, and deepened the cooperation intention in school-enterprise cooperation. In the next step, Delphilaser will join hands with Soochow University to provide more opportunities for the sustainable development of talents and promote the integration of production, education and research on both sides to a new level. This article belongs to Suzhou Delphi Laser Co., Ltd.(www.delphilaser.com), if reproduced, please indicate the company name and website For more information about our products and applications, please visit our website at: Delphilaser official website:www.delphilaser.com Ali store:tbdelphilaser.com Or scan the following two-dimensional code to follow our WeChat service number

2022-04

Today, Suzhou Suzhou Delphi Laser Co., Ltd. was officially listed on the Science and Technology Board of the Shanghai Stock Exchange(Stock short name: Delphilaser, stock code: 688170)。 Dr. Zhao Yuxing, founder, chairman and general manager of the company; Mr. Zhang Jun, shareholder representative and general manager of Strategic Development Department and Mr. Yao Hua, shareholder representative and managing partner of Yuanhe Chongyuan Fund, sounded the gong to open the market. Yuan Ling, Li Suyu, Yan Hua, Gu Yejue, Yuan Gongshu, Li Jinai, Di Jianke, Chengzhong, Xu Haibin, Wu Zhonggang, Liu Haili and Li Liwei, representatives of the company management, witnessed this historic moment. In his speech, Dr. Zhao Yuxing, founder, chairman and general manager of Delphilaser, expressed his deepest gratitude to the government leaders at all levels, the Securities and Futures Commission and the SSE for their care and guidance, to all shareholders for their trust and support, to industry experts and scholars for their help, to all customers and suppliers and other partners for their support, to the intermediaries for their help, and to the financial community, the media and partners from all walks of life for their care. Sincere thanks. Dr. Zhao said he would lead the company to take the listing as a new starting point, and continue to deepen product development, technological innovation and management innovation to achieve faster and better development with the power of the capital market. The company shoulders the mission of "creating a micro and nano world with laser", strengthens the core technology development and market competitiveness, devotes to become a laser company with global influence in the field of fine micro processing, and realizes the win-win situation for customers, employees, society and shareholders. Suzhou Industrial Park, as one of the regions with the highest degree of openness, the best development quality and efficiency, the strongest innovation vitality and the best business environment in China, provides strong guarantee and high-quality services for the development of Delphilaser. On the occasion of the listing of Delphilaser, the management committee of the park also sent a congratulatory letter, encouraging the company to take the listing as a new starting point, continue to deepen technological innovation, management innovation and business model innovation, be the industry leader, climb a new peak of professionalism, and make new contributions to the high-quality development of the park! As the sponsor and lead underwriter of Delphilaser's IPO, CITIC Capital Securities warmly congratulates Delphilaser on its successful issuance. In the future, CITIC Capital Securities will effectively fulfill its responsibility of continuous supervision, continue to provide multi-faceted capital market services, help Delphilaser develop healthily and reward investors. Along with the upgrading of China's manufacturing industry, focusing on the direction of high technology content and good application prospect, Delphilaser has been dedicated to research and development, conquering key core technologies, breaking foreign monopolies, and empowering modern manufacturing with advanced lasers. After years of research and development, the company has obtained 36 invention patents, more than 110 utility model patents and 60 software copyrights, and has been honored as a key high-tech enterprise under the National Torch Plan and a "Small Giant" enterprise under the National Specialized Precision and New Enterprise. The company's products and technologies have been unanimously recognized by leading downstream enterprises, establishing the company's market position in China's laser fine microprocessing industry. In the future, Delphilaser will continue to strengthen its core technology, continuously launch new products, commit to become a laser company with global influence in the field of fine micro processing, and create more excellent business performance to reward investors and society. With the opportunity of listing on the board, Delphilaser will achieve leapfrog development and work hand in hand with investors to create a bright future together!