2025-05

From May 15 to 17, 2025, the highly influential battery industry event - the 17th Shenzhen International Battery Fair (CIBF2025) was grandly held in Shenzhen. Delphi Laser showcased multiple advanced lithium battery manufacturing solutions including roll-to-roll laser baking equipment, roller press laser online cleaning systems, lithium battery echelon utilization, and 500W femtosecond lasers.Using precision laser micromachining technology to empower intelligent lithium battery manufacturing, Delphi Laser's booth attracted tremendous popularity and became the focal point of the exhibition! Focusing on details and continuous innovation. At this year's CIBF2025, Delphi Laser concentrated on technological innovation, bringing multiple industry-first innovative solutions that focused on the entire process upgrade in the lithium battery field, attracting extensive attention from numerous exhibition visitors and partners. During the exhibition, Delphi Laser also gave presentations on topics including laser drying, all-solid-state battery applications, ultrafast lasers, and battery pack laser disassembly processes, engaging in in-depth exchanges and discussions with many industry professionals on site to share the latest research and application achievements. Presentation scene Accepted live interview by Gaogong Cloud Exhibition Delphi Laser looks forward to meeting you next time! Please continue to follow Delphi Laser!

2025-03

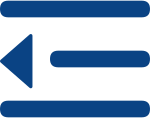

The 2025 LASER World of PHOTONICS CHINA successfully concluded. Delphi Laser, with innovative technologies and excellent products at its core, demonstrated cutting-edge laser solutions across multiple fields, receiving high recognition both within and outside the industry! Keynote Speeches During the exhibition, seven keynote speeches directly addressed industry pain points. Technical experts shared the latest R&D achievements and market prospects, creating an enthusiastic atmosphere on site! On-site Highlights Delphi Laser's booth was crowded with visitors. On-site audiences and partners experienced the charm of precision laser micro-processing up close, while jointly exploring its wide applications and future potential in the industry. On-site Activities The 2025 LASER World of PHOTONICS CHINA successfully concluded. Delphi Laser will continue to use "New Quality Productivity" as its engine, deepen laser applications and cutting-edge technologies, and drive innovative development in the industry!

2025-01

Recently, the China National Intellectual Property Administration (CNIPA) announced the eva1uation results of the 25th China Patent Awards. Suzhou Delphi Laser Co., Ltd. was honored with the "China Patent Excellence Award" for its patent titled "Device and Method for Asymmetric Beam Splitting Laser Processing of Transparent Materials", further demonstrating the company's strength in technological innovation. Since its establishment in 2005, Delphi Laser has consistently aligned with national R&D demands, placing high importance on intellectual property (IP) and actively advancing its IP-driven corporate strategy. The company has set up a dedicated IP management department, formulated strategic IP plans, and enhanced overall IP awareness. These efforts have earned it the titles of "National Intellectual Property Advantage Enterprise (2019)" and "National Intellectual Property Demonstration Enterprise (2022)". Moving forward, Delphi Laser will continue to uphold the principle of innovation-driven development, leverage its exemplary role, increase R&D investment, and actively explore new technologies and applications to enhance its core competitiveness. The company remains committed to achieving its goal of becoming a globally competitive IP powerhouse. About the China Patent Awards: Co-organized by the CNIPA and the World Intellectual Property Organization (WIPO), the China Patent Awards represent the only government-backed accolade in China that recognizes outstanding patented inventions. The awards aim to strengthen IP creation, protection, and utilization, promote high-quality economic development, and honor patentees and inventors (designers) who have made significant contributions to technological innovation and socio-economic progress.

2024-11

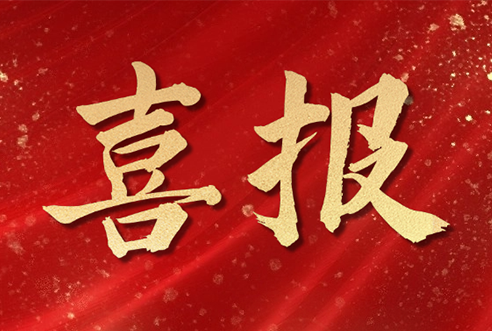

In November, the autumn breeze in Suzhou is just right, and Delphi Laser's annual marathon event is once again underway. The people of Dephi Laser, with their spirited attitude, measure the earth with their footsteps and write perseverance with their sweat. Wonderful Moments On the racecourse, the athletes from Delphi Laser showed exceptional style, surpassing themselves, moving forward courageously, and never giving up! It is worth mentioning that the female participants in this year's marathon competition were no less than their male counterparts, becoming a beautiful sight on the track. Award Group Photos 20km Group 10km Group 5km Women’s Group 5km Men’s Group Team Award: Operations Center Running never stops, and innovation continues without end. All employees of Delphi Laser will approach their work and life with greater enthusiasm, a strong body, and a spirited attitude. Looking ahead, Delphi Laser will run hand-in-hand with partners both inside and outside the industry to create brilliance together! Looking forward to next year’s Delphi Laser Marathon, continuing to create even more wonderful moments!

2024-09

Material Innovation, Empowering Development Delphi Laser As the foldable smartphone market continues to surge, innovative materials have become the key to advancing this technology. This has heightened the demand for high-precision laser processing equipment. Delphi Laser, with its deep expertise and commitment to innovation, has strategically positioned itself in the foldable screen market. Its equipment has been successfully deployed in production lines, earning high recognition from clients and providing precise, efficient solutions for intelligent manufacturing in every detail of foldable smartphones. 1、Cover Glass Processing Delphi Laser 1)UTG Glass Cutting System Ultra-Thin Glass (UTG) is increasingly favored for foldable display covers due to its ultra-thin, flexible, highly transparent, and high-temperature-resistant properties. Addressing the growing demand for UTG, Delphi Laser offers specialized UTG glass cutting equipment that ensures high-efficiency, precise cutting, enhancing production efficiency and yield rates. Advantages: Non-contact processing minimizes material damage and operating costs. High-speed, precision cutting with CCD vision alignment. Direct CAD import for quick and efficient cutting of various shapes. Industrial-grade design ensures stable 24/7 operation. Optional automated loading/unloading for increased efficiency and reduced labor. Samples: 2)CPI Laser Precision Micro-Processing System Transparent Polyimide (CPI), a critical material for foldable screens, offers stable performance, technical maturity, and cost advantages. Delphi Laser's CPI micro-processing equipment delivers high-precision, efficient cutting tailored to this key material. Advantages: High-speed processing with excellent precision, boosting productivity. Minimized thermal effects, reducing edge chipping. Advanced processing systems enable precise parameter and pattern matching. 3)Film Cutting and Stripping Integrated System This automated solution protects display covers from scratches and stains by efficiently handling film application and stripping. Delphi Laser’s cutting-edge design integrates laser cutting, vision alignment, and automated systems for seamless operation. Advantages: Automated tray transfer and robotic loading enhance productivity. Precision alignment ensures accurate cutting and film application. Customizable settings for various dimensions and positions. Stable, long-term operation supported by high-quality materials and software. 2、Carbon Fiber Processing Delphi Laser Carbon Fiber Cutting System Carbon fiber, known for its lightweight and high-strength properties, is essential in foldable smartphone structural designs. Delphi Laser’s advanced carbon fiber cutting equipment ensures smooth, burr-free edges and optimized production efficiency. Advantages: High-speed, precise cutting reduces thermal effects and edge damage. Integrated systems for automated loading, cleaning, waste removal, and inspection. High-power laser systems developed in-house for cost-effective, high-performance processing. Samples: 3、Metal Hinge Processing Delphi Laser Hinge Laser Welding System Metal hinges are critical components in foldable smartphones, providing structural support and enabling various folding mechanisms. Delphi Laser’s laser welding equipment ensures precise, high-quality welding for hinges, accommodating a variety of materials and designs. Advantages: Fast Welding Speed: Laser welding achieves high speed, significantly enhancing production efficiency and meeting the rapid manufacturing demands of foldable smartphones and other electronic products. Non-Contact Welding: As a non-contact process, laser welding minimizes stress impact on metal components. Controllable Welding Depth: By adjusting laser power and beam focus, precise control of welding depth is achieved, preventing defects from excessive or insufficient penetration. High Adaptability: Laser welding technology accommodates various sizes, shapes, and materials of metal hinges, offering greater design flexibility for foldable smartphones. Samples: 4、Flexible OLED Processing Delphi Laser 1)Fully Automated Flexible OLED Shaped Cutting System This system is capable of easily handling complex shapes and curved cutting requirements. It precisely addresses the intricate folding shapes of smartphones. The equipment is primarily used for the fine-tuning and processing of AMOLED module segments, where the OLED panels are integrally cut by laser to improve edge precision and achieve irregular shape cutting. The system is equipped with an automatic image positioning system, multiple feeding and unloading interfaces, AOI (Automatic Optical Inspection), and USC (Ultrasonic Cleaning), ensuring efficient high-speed cutting and stable, high-quality operation. Advantages: It uses a UV picosecond/femtosecond laser combined with a galvanometer scanning system, enabling fast irregular shape cutting. Cutting quality: HAZ (Heat-Affected Zone) ≤ 50μm Cutting precision: CPK ≥ 1.33 (@±30μm) Fully automated Inline/Offline design, further reducing labor costs Compatible with OCA integrated cutting Samples: 2)Fully Automated Flexible OLED Laser Drilling System The core of a foldable smartphone lies in its foldable screen, which must maintain excellent performance and appearance during both folding and unfolding. Delong Laser's fully automated flexible OLED laser punching equipment is specifically designed for the AMOLED module display area. It uses advanced laser technology for punching the OLED panels in the AMOLED module to expose components such as the camera and other devices. By precisely controlling the laser energy and beam quality, it provides a reliable solution for manufacturing flexible display devices. Advantages: Utilizes UV femtosecond laser with a scanning galvanometer system to meet the demand for fast laser punching. Cutting quality: HAZ ≤ 40μm, no cracks, no rainbow patterns. Cutting precision: CPK ≥ 1.33 (@ ±30μm). Samples: 3)OLED/LCD Laser Repair System In the development of foldable smartphones, the perfect presentation of each pixel is an unwavering pursuit of quality. Delong Laser's OLED/LCD laser repair equipment is equipped with high-precision laser technology and advanced AOI (Automated Optical Inspection) technology, providing excellent imaging quality. The chosen control system components are highly precise, enabling the automatic detection and accurate positioning of OLED/LCD screen hotspots. Whether dealing with bright spots, weak bright spots, or partial dark spots, laser repair can be performed. The equipment features a compact structure and operates stably and reliably. Key Advantages: The equipment features a compact structure with a well-organized layout. It offers excellent compatibility. The motion system is stable and responsive. It delivers high precision, user-friendly interfaces, and easy maintenance. A strong technical team provides robust support for equipment installation, commissioning, and after-sales maintenance. Samples: 5、PCB/FPC Processing Delphi Laser Picosecond Laser Precision Micro-Processing System PCB and FPC play crucial roles in foldable smartphones, together forming the complex and precise circuit system that ensures the normal operation and exceptional performance of the device. Delphi Laser's picosecond laser fine processing equipment, with its high precision, efficiency, and stability, is widely used in the fine processing fields of cutting, lid opening, and other applications for PCB, FPC rigid-flex boards, and related materials in foldable smartphones. The equipment utilizes advanced picosecond laser technology, meeting the stringent processing precision requirements for high-end electronic products such as foldable smartphones. Key Advantages: The equipment uses an independently developed high-power ultraviolet picosecond laser, offering high cost-effectiveness. It effectively controls the processing results, improving product edge collapse and thermal effects. The self-developed dual-station processing system is stable and reliable, significantly improving processing efficiency. The mature process system accurately calculates and splits graphics, ensuring the precise matching of processing parameters and design patterns. Innovation never stops, empowering the future Delphi Laser Future Outlook Delphi Laser remains committed to innovation and excellence in laser micro-processing. By continuously advancing its technology, Delphi Laser empowers intelligent manufacturing, shaping the future of foldable smartphones and beyond.

2024-06

As a global trendsetter in the photovoltaic industry, the three-day 17th International Solar Photovoltaic and Smart Energy Conference & Exhibition (2024 SNEC) concluded successfully in Shanghai on June 15. Delphi Laser showcased perovskite thin-film solar cell laser applications, advanced crystalline silicon manufacturing solutions, and screen printing laser applications, attracting significant attention from exhibitors and industry clients worldwide. Perovskite GW Line Laser + Packaging Integrated Solution This equipment is used for etching the internal series circuit of perovskite thin-film solar cells. The equipment integrates multiple laser sources and can complete P1/P2/P3 scribing, P4 edge cleaning, P5 light-transmitting component processing, and P6 cutting and splitting in the perovskite cell production process. Roll-to-Roll Flexible Thin-Film Solar Cell Laser Scribing System This equipment is uses high-energy lasers for scribing on glass surfaces. Depending on the laser configuration, different processes can be performed. The equipment's components are efficiently integrated to achieve high-precision, high-speed scribing, and etching processes. BC Cell Laser De-coating Isolation Processing System This equipment is used for de-coating BC cells. It enhances the performance of the back passivation layer by reducing carrier recombination loss at the interface, thereby improving photoelectric conversion efficiency. TOPCon Laser Enhanced Sintering System This equipment is designed to improve contact resistance in crystalline silicon solar cells. It reduces metal-semiconductor recombination loss, improving the contact resistance between the electrode grid and the crystalline silicon cell, thereby enhancing the photovoltaic conversion efficiency of crystalline silicon cells. High-Precision Laser Screen Etching System This equipment is equipped with an ultrashort pulse UV laser, combined with high-performance peripheral components. It is primarily used for drilling and cutting PI and other materials. It can process photovoltaic and non-photovoltaic patterns on PI screens and is also capable of processing SE screens and knotless screens at the current stage. Delphi Laser looks forward to seeing you next time. Stay tuned to Delphi Laser!

2024-03

The three-day Laser World of Photonics China 2024 and SEMICON China 2024 have successfully concluded. Delphi Laser made a grand appearance with multi-field laser solutions, showcasing the company's achievements in technological development and product innovation, attracting numerous customers for communication and cooperation discussions! Let's take a look back at the highlights of this exhibition. ▼▼▼ At this year's photonics exhibition, Delphi Laser hosted six themed presentations focusing on laser precision micro-machining solutions, showcasing cutting-edge and innovative laser application cases, creating a lively atmosphere for on-site exchanges! Media Interviews Highlights from both exhibitions Delphi Laser looks forward to seeing you next time. Stay tuned to Delphi Laser!

2024-05

On May 8th, the Photonix 2024, an international photonics and laser exhibition in Japan, grandly opened at INTEX Osaka. Suzhou Delphi Laser Co., Ltd.'s wholly-owned subsidiary, Delphi Laser Japan Co., Ltd., showcased a variety of laser solutions once again at the exhibition. The event received widespread attention and high praise from both industry insiders and the general public! Delphi Laser looks forward to seeing you next time. Stay tuned to Delphi Laser!