Wafer Laser Grooving System

The AS-5380 uses a high quality light beam to perform surface scribing and grooving in the wafer dicing channel.

Inquiry Phone:+86-400 8017 001

Inquiry Phone:+86-400 8017 001 E-mail:contact@delphilaser.com

E-mail:contact@delphilaser.com■ Specifications:

◆ Applicable materials: Low-k, metal, ceramic, glass, etc.

◆ Laser type: DPSS ultraviolet laser

◆ Laser power: ≥5W

◆ Cooling method: Closed-loop water cooling

◆ Grooving depth: >10μm

◆ Cutting-axis speed: 0-800mm/s

◆ Applicable wafer size: 12 inches

◆ Upper surface precision: 0.01mm/300mm

◆ Cleaning plate rotation speed: 2500r/min

◆ Rotational accuracy: 0.01°

◆ Processing method: Automatic front-side grooving

◆ Focusing mode: Auto-focusing

◆ Lighting system: Point light source

■ Advantages:

◆ Effectively reduce edge collapse and delamination, improving yield.

◆ Grooving width and depth are adjustable.

■ Applications:

◆ Surface grooving of low-k wafer used in the 40nm or smaller process.

◆ Surface scribing or grooving of semiconductor wafer.

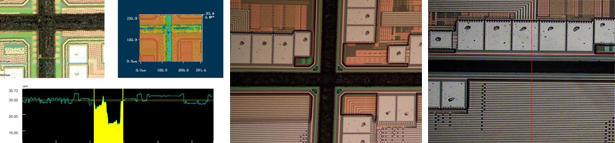

■ Samples:

For more information