Wafer Laser Stress-Induced Dicing system

This system uses stress-induced cutting technology to process and cut Mini LED wafers.

Inquiry Phone:+86-400 8017 001

Inquiry Phone:+86-400 8017 001 E-mail:contact@delphilaser.com

E-mail:contact@delphilaser.com■ Specifications

◆ Laser type: DPSS picosecond laser

◆ Laser power: ≥1W

◆ Cooling method: Closed-loop water cooling

◆ X-axis: 360mm travel length, 0.1μm resolution

◆ Y-axis: 300mm travel length, 0.1μm resolution

◆ Z-axis: 15mm travel length, 1μm resolution

◆ θ-axis: ±60° travel angle, 0.0001° resolution

◆ Scribing speed ≤ 1000mm/s

◆ Throughput of 4-inche wafer:15pcs/h@10*30mil (4-inche wafer)

◆ Applicable wafer size: 2 or 4 inches (can be outfitted to 6-inch wafers)

◆ Optional dual spot processing capability

■ Advantages

◆ Fast cutting speeds, pause-less process

◆ High production capacity and yield rates, stable performance

◆ No consumables, Low operating costs

■ Applications

Straight Cutting of Sapphire Substrate Wafers for LED Lighting Industry

Straight Cutting of Sapphire Material for Other Industries

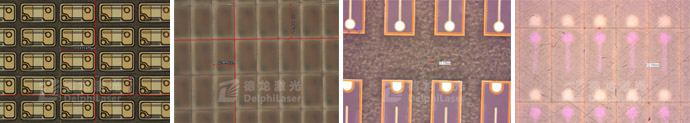

■ Samples

For more information