2020-08-24 09:24:20

This article belongs to Suzhou Delphi Laser Co., Ltd.(www.delphilaser.com), if reproduced, please indicate the company name and website

2020 Laser Industry - Ringier Technology Innovation Award Ceremony was held in Shanghai Longemont Hotel this afternoon, after the intense and intense selection of expert panel judges, the major awards were finally announced!

Delphilaser's 2018 Silicon Carbide Wafer Laser Cutting Equipment Wins "Ringier Technology Innovation Award" in the Laser Processing Systems Category

Head of Semiconductor Division - Mr. Jiang Xiang (second from left)

Head of Semiconductor Division - Mr. Jiang Xiang

Head of Semiconductor Division - Mr. Jiang Xiang (first from right)

2020 Laser Industry - Ringier Technology Innovation Award

Silicon Carbide Wafer Laser Cutting Equipment

The silicon carbide wafer laser cutting machine utilizes an ultra-short pulse laser to achieve high quality and efficient cutting of silicon carbide wafers.

Development Background

▼

SiC semiconductor (here 4H-SiC) is the 3rd generation semiconductor, which has the advantages of high critical breakdown electric field and high electron mobility, and is an excellent semiconductor material for manufacturing high-voltage, high-temperature, irradiation-resistant power semiconductor devices, and is currently used in power electronics and GaN-on-SiC RF Fields.

Conventional silicon wafers, most of the use of abrasive wheel Cutting, abrasive wheel Cutting using the participation of diamond particles of the abrasive wheel blade, the use of high-speed rotation of the blade to remove the material, in order to achieve the wafer cut. Silicon carbide has a Mohs hardness of 9.5, which is second only to diamond, so if wheel blades are used for Cutting, the speed of material removal will be very slow, so the scribing efficiency will be very low and the wear and tear of the blades will be very serious. So the wafer Cutting of silicon carbide substrate becomes a problem.

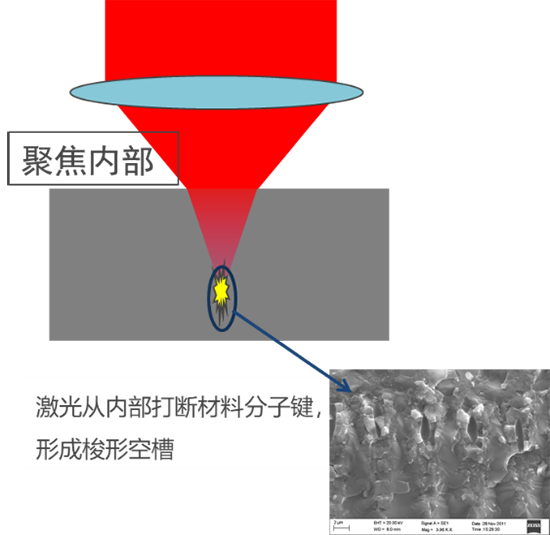

Delphilaser's stress-induced cutting method is good at cutting super hard and super brittle materials. Stress-induced cutting means focusing the laser to the inside of the material, breaking the molecular bonds of the material from inside, and releasing the hard force of the material. Through our research and development, we have successfully achieved high quality and rapid cutting of silicon carbide wafers using the laser stress-induced cutting method.

Process Advantages

▼

• Use of ultra-short pulse laser, strong penetration and effective avoidance of thermal effects to achieve invisible Cutting

• Provide complete solutions for customers by providing supporting lobe & wafer expansion equipment

• The process is mature and can cut different types of silicon carbide wafers.

Applications

▼

• Cutting of silicon carbide power electronics wafers

• Cutting of SiC-based GaN RF chips

Processing results

▼

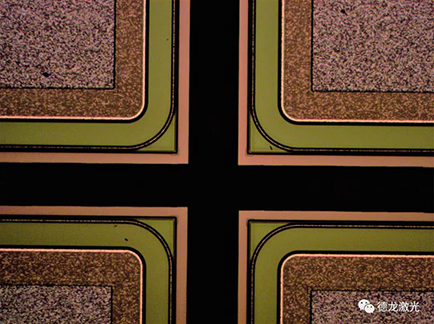

Cutting effect of SiC wafers with 175um thickness

Cutting effect of SiC wafers with 350um thickness

We thank Ringier Industrial Media for providing a platform for product innovation and technology exchange in the industry and the expert judges for their affirmation and support of Delphilaser.

With the mission of creating a micro-nano world with laser, Delphilaser people will continue to work hard and move forward hand in hand to pursue light and dream, and create a smart future.

This article belongs to Suzhou Delphi Laser Co., Ltd.(www.delphilaser.com), if reproduced, please indicate the company name and website

For more information about our products and applications, please visit our website at:

Delphilaser official website:www.delphilaser.com

Ali store:tbdelphilaser.com

Or scan the following two-dimensional code to follow our WeChat service number